support@comsol.com

Metal Processing Module Updates

For users of the Metal Processing Module, COMSOL Multiphysics® version 6.2 introduces a new feature to model annealing, options to define the chemical composition of hypoeutectoid steels, and improvements for phase transformation analysis in both memory consumption and computational time. Read more about these updates below.Modeling Annealing

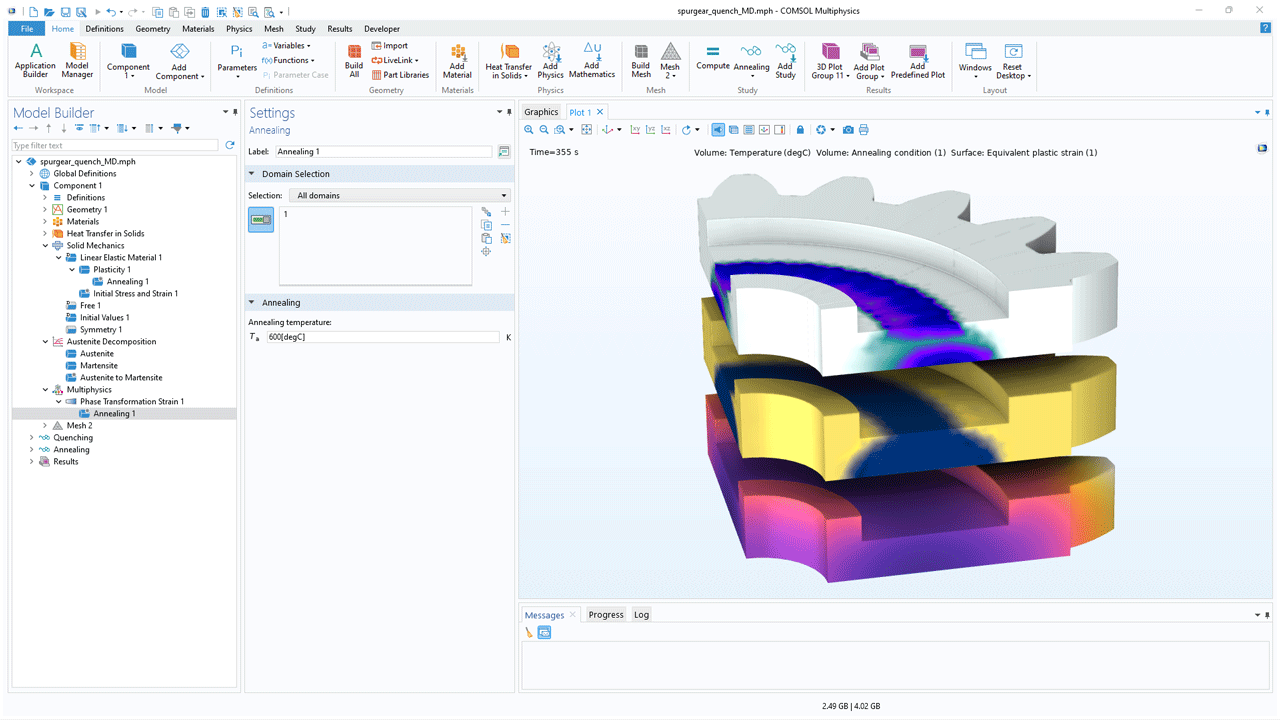

In some cases, it is necessary to model heating of steel that has undergone plastic deformation. If temperatures are sufficiently high, previous work hardening is recovered, and this effect should be included in the computational model. A new Annealing subnode to the Phase Transformation Strain multiphysics coupling provides the ability to define an Annealing temperature above which prior work hardening of the steel is removed. Plastic hardening variables are reset when the temperature exceeds the specified annealing temperature. This is useful in situations where the material undergoes thermal cycling, such as during multipass welding, and where the residual stress state is strongly affected by the plastic history of the material. The Annealing subnode must be used in conjunction with Annealing subnodes to Plasticity nodes of the coupled Solid Mechanics interface. Note that this feature requires the Nonlinear Structural Materials Module.

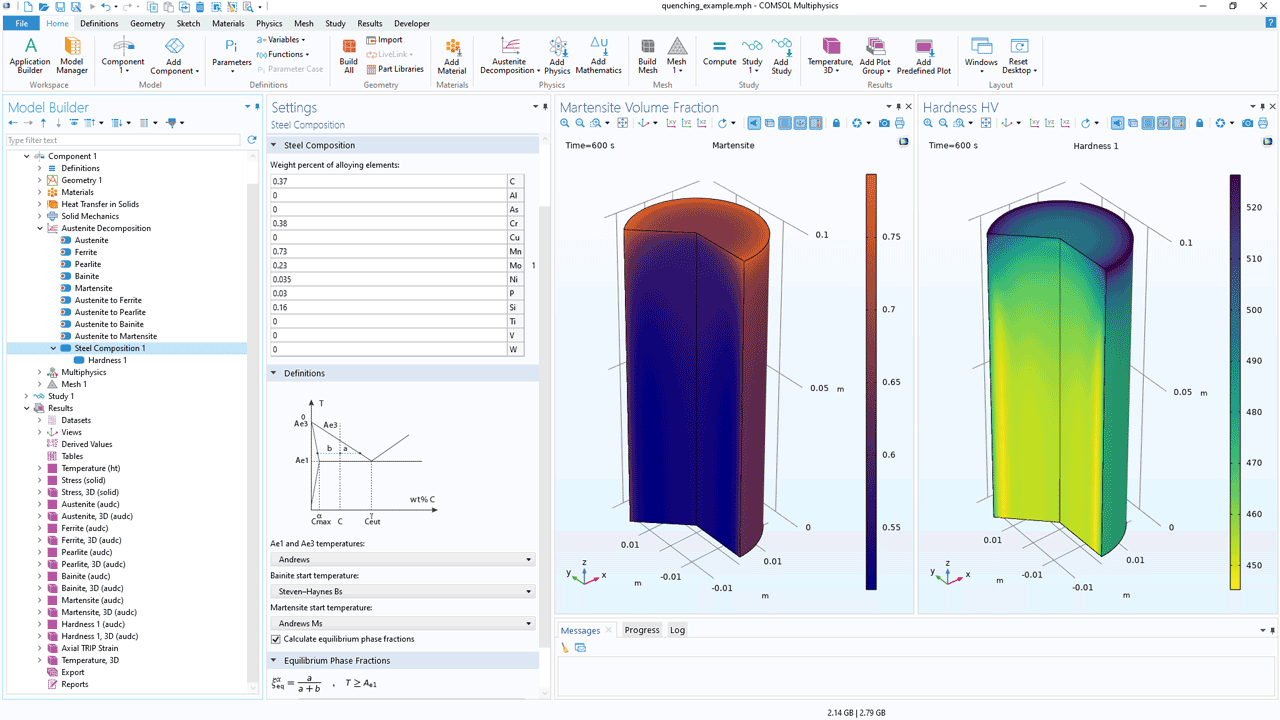

Steel Composition and Hardness

A new Steel Composition feature is available to specify the chemical composition of hypoeutectoid steels. Using proposed models in the literature for different transformation temperatures, an iron–carbon (Fe–C) diagram is constructed in the software and then used to define start and finish temperatures during austenite decomposition. In addition, different models are provided for equilibrium phase fractions, such as the equilibrium phase fraction of ferrite in the two-phase ferrite–austenite region of the Fe–C diagram. It is also possible to calculate the Vickers hardness (HV) after quenching using the new Hardness subnode under Steel Composition.

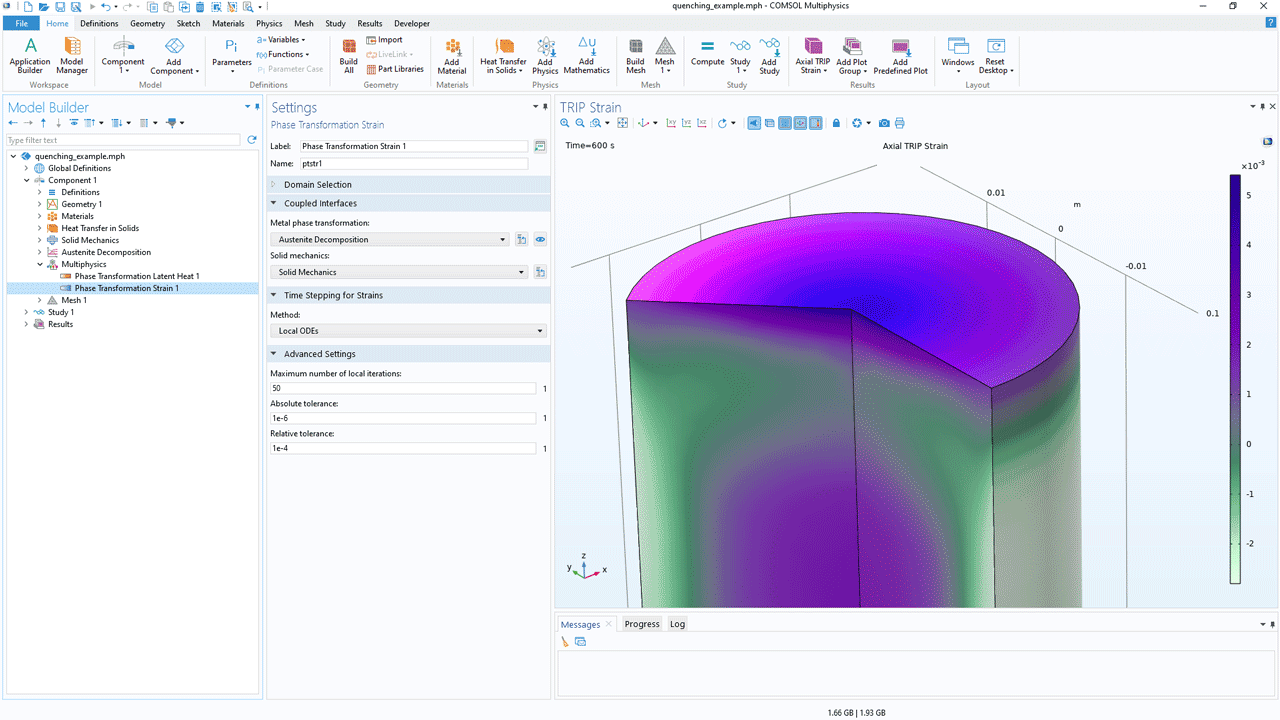

Performance Improvements

The equations describing both transformation-induced plasticity (TRIP) strain evolution and plastic strain recovery are now solved using a local, implicit time procedure, resulting in reduced memory consumption, shorter computational time, and overall performance improvements. Specific settings for the local time integration procedure can be changed within the Phase Transformation Strain multiphysics coupling by clicking the Show More Options button in the Model Builder toolbar and enabling Advanced Physics Options.