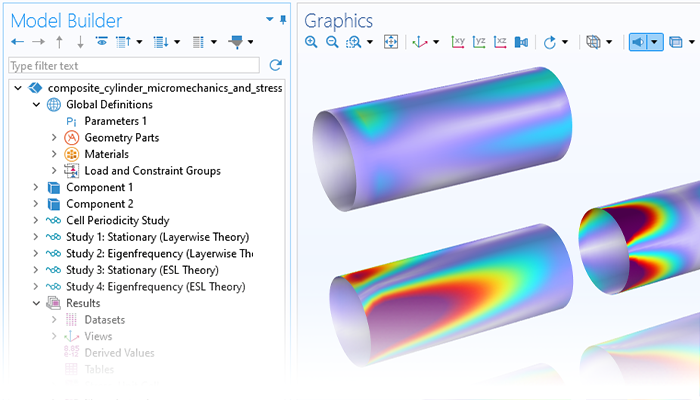

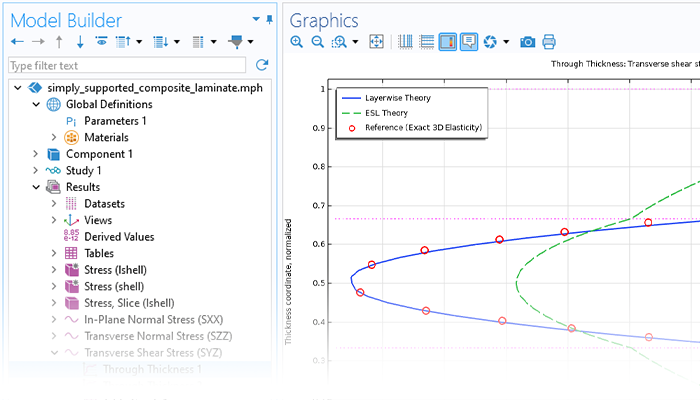

The Composite Materials Module utilizes specialized layered material technology and provides two theories that can be used to accurately model composite shells: layerwise theory and equivalent single layer theory. The layerwise theory is suitable for thick to moderately thin composite shells with a limited number of layers. The equivalent single layer theory is suitable for thin to moderately thick shells and can accommodate many layers without significant performance impact. It is also possible to combine these two theories to analyze the composite laminates. Using these theories, you can optimize the layup and other parameters of a laminate by performing multiscale, multiphysics, and various failure analyses.

Composite Materials Module

Model Composite Structures for Improved Product Design

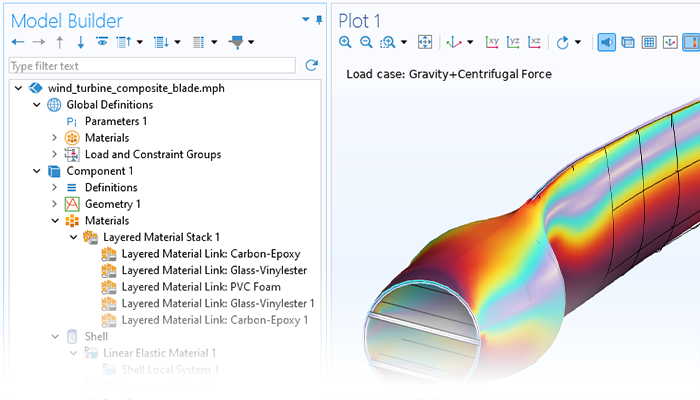

A composite material is a heterogeneous material composed of two or more integrated constituents for enhanced structural performance. The Composite Materials Module is an add-on to the Structural Mechanics Module that brings you specialized modeling tools and functionality for analyzing layered composite structures. Layered composite materials, such as fiber-reinforced polymers, laminated plates, and sandwich panels, are widely used in manufacturing aircraft components, spacecraft components, wind turbine blades, automobile components, buildings, boat hulls, bicycles, and safety equipment.

Additionally, when you combine the Composite Materials Module with other modules from the COMSOL product suite, you can extend your models to include heat transfer, electromagnetics, fluid flow, acoustics, and piezoelectric effects — all within the same simulation environment.

Contact COMSOL

Laminate Theories to Define and Visualize Laminates

The analysis of laminated composite shells is commonly based on three-dimensional elasticity theory or equivalent single layer (ESL) theory.

What You Can Model with the Composite Materials Module

Perform various structural analyses for composite laminates with the COMSOL® software.

Micromechanical/Macromechanical

Compute homogenized material properties and macroscopic responses of composite laminates.

Multiscale Analysis

Evaluate the structural response of a composite structure both at the macroscale and at the microscale.

Nonlinear Materials1

Incorporate nonlinear material models in a layered composite.

Delamination

Model delamination initiation and propagation in a composite plate.

Linear Buckling

Compute critical load factors and mode shapes under compressive loading.

First-Ply Failure

Evaluate the structural integrity of a laminated composite shell.

Composite Optimization2

Optimize composite layups, ply thicknesses, fiber orientations, and material properties.

Structural Connections

Couple composite laminates with other structural elements from various structural mechanics interfaces.

- Additionally requires the Nonlinear Structural Materials Module

- Additionally requires the Optimization Module

Specialized Tools for Defining and Visualizing Laminates

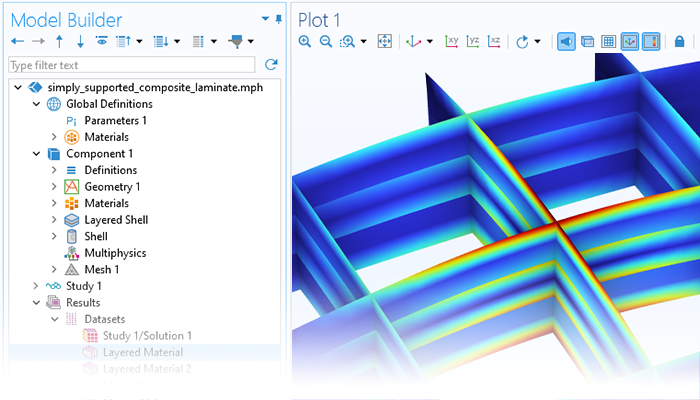

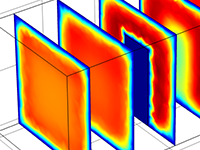

The Composite Materials Module offers a set of specialized tools for visualizing composite laminates that are made up of several layers.

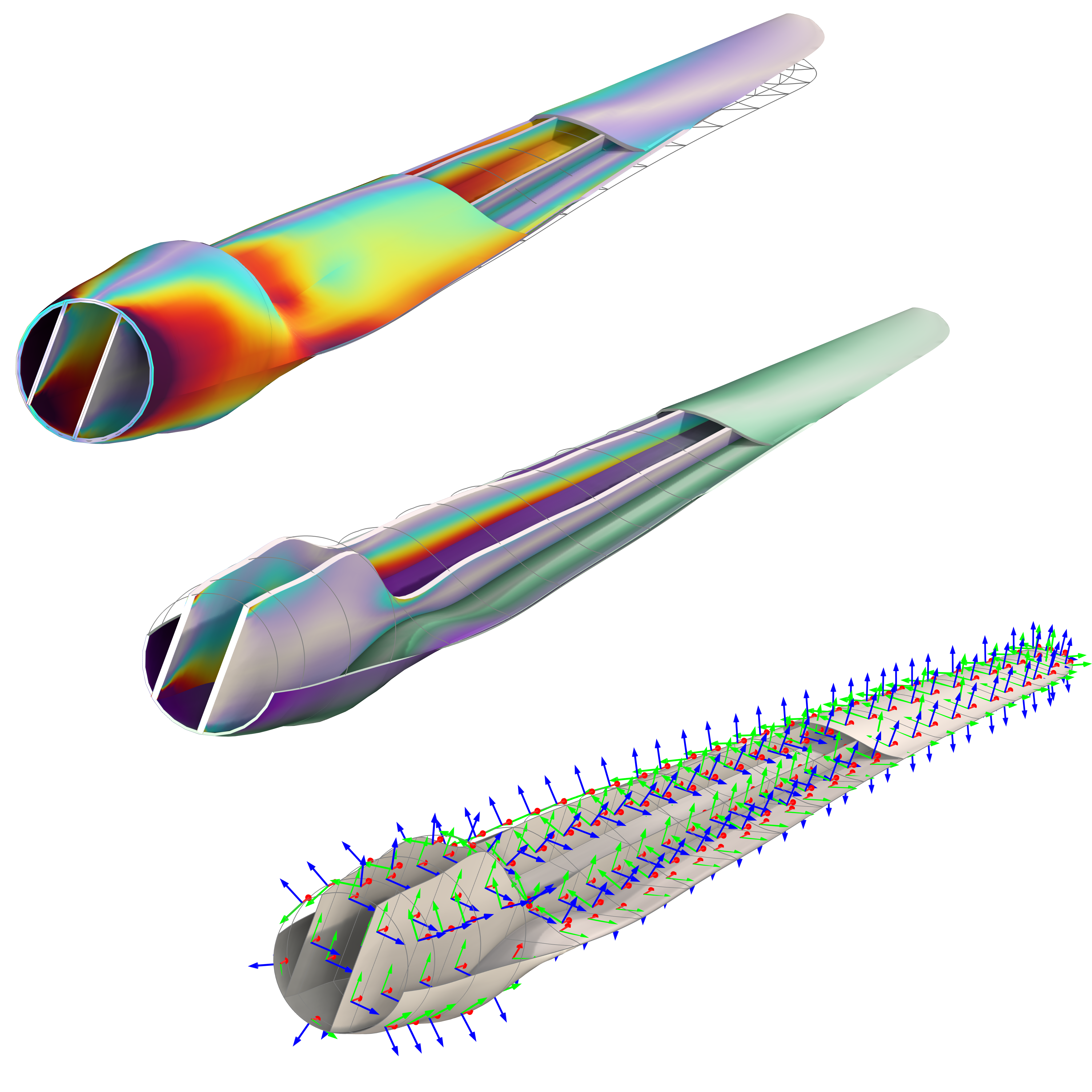

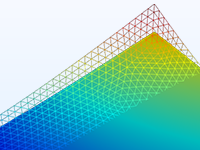

Layerwise Approach/Layered Shell Interface

The Layered Shell interface, available in 3D, provides an approach based on layerwise theory for a detailed analysis of composite laminates. The materials in the individual layers can be nonlinear. It also supports different shape order for the displacement field in the reference surface and in the through-thickness direction. The results include full 3D stress and strain distributions, so you can compute interlaminar stresses and study stress variations inside each lamina, for example.

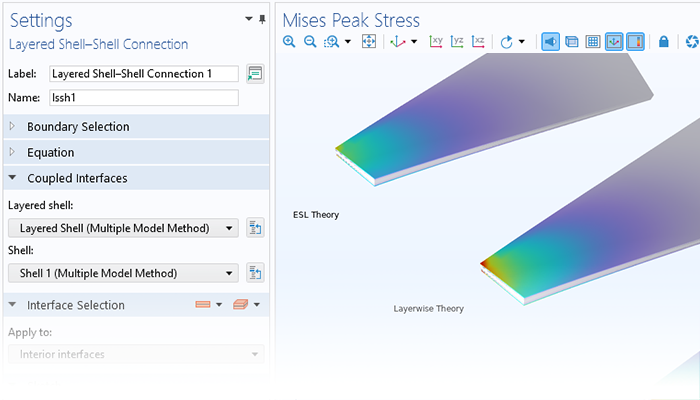

Mixed Approach/Multiple Model Method

The Layered Shell interface based on layerwise theory is accurate but computationally expensive. The Shell interface based on an equivalent single layer theory is computationally lean but unable to capture accurate through-thickness results. The multiple model method — which combines these two theories in the different parts of a composite laminate — is the best choice in terms of accuracy and performance for modeling sandwich composite structures.

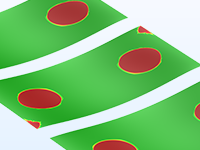

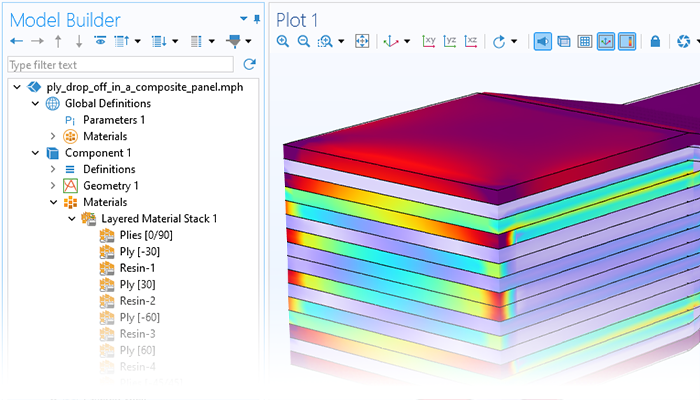

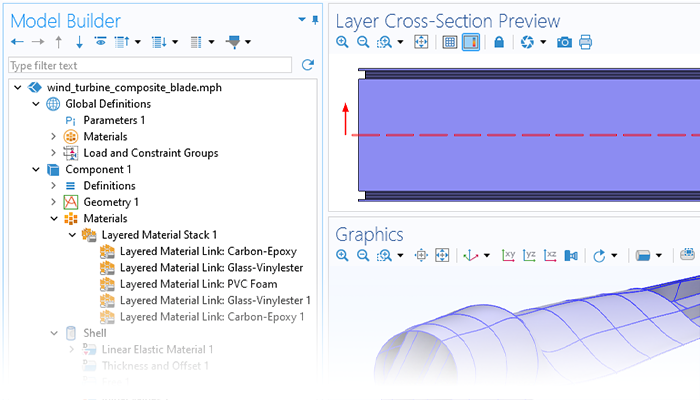

Layered Material Feature

The Layered Material node can be used to define a layup where each layer has its own material data, thickness, and principal orientation. You can also define material properties for the interfaces between layers. Layered materials defined in this way can be combined using the Layered Material Link or Layered Material Stack node to create more complex layered materials, which is particularly convenient when the layup is repetitive, symmetric, or antisymmetric. These nodes include action buttons for visualizing the 2D or 3D preview plots of composite laminates.

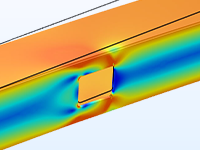

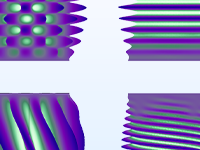

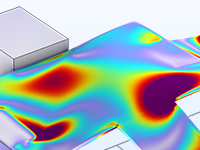

Layered Material Slice Plot

The Layered Material Slice plot provides more freedom in terms of creating slices in a composite laminate. It is useful when creating a slice only through one or a few selected layers or creating a slice through some or all layers, but not necessarily placing them in the through-thickness direction. It can also be used when examining a particular layer in detail and creating a slice at a particular position within the layer that is not the midplane.

Equivalent Single Layer Approach/Shell Interface

The Shell interface is augmented with a material model, based on an equivalent single layer theory, that computes homogenized material properties of the entire laminate and solves only at midplane. Various inelastic effects like plasticity and viscoplasticity can be added to the individual layers of the laminate. The results include full 3D stress and strain distributions, so you can study stress variations inside each lamina, for example.

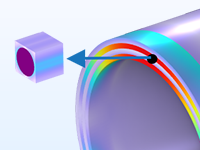

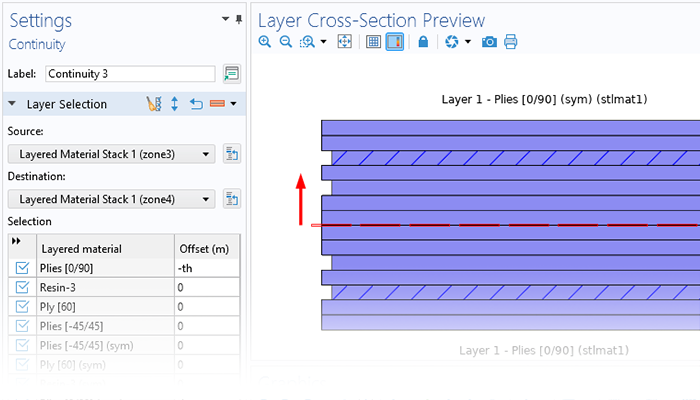

Layered Material Connection/Continuity

When joining two different laminates in a side-by-side configuration or modeling a ply drop-off situation, it is possible to use the Layered Material Stack node together with the Continuity node in the Layered Shell interface. The connection area of the two laminates can be controlled through different options. The connected layers from both the laminates can be visualized using the Layer Cross Section Preview plot available in the Continuity node.

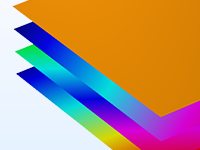

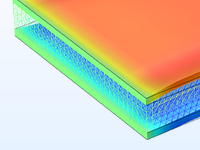

Layered Material Dataset

The Layered Material dataset is used to display the results of the simulation on a geometry that has a finite thickness. With this dataset, you can scale the laminate thickness in the normal direction, which is useful for visualizing thin laminates. The dataset offers the option to evaluate results at mesh nodes, interfaces, or layer midplanes, and it is also possible to select or deselect certain layers of a laminate.

Through Thickness Plot

The Through Thickness plot enables you to visualize the variation of any quantity at a particular position on the boundary against the laminate thickness. You can select one or more geometric points on the boundary or optionally create cut point datasets. It is also possible to specify the point coordinates directly. Unlike other graphs, the result quantity is plotted on the x-axis, while the thickness coordinate is plotted on the y-axis.

Multiphysics Couplings for Extended Analyses

There are two fundamentally different types of interaction between the mechanics in the laminate and other processes. For physical processes that occur inside the laminate, you can solve for all of the physical phenomena simultaneously, including the couplings between them. In other physical processes, the laminate acts as a boundary for a 3D domain where something important occurs. The following multiphysics couplings are available with built-in couplings:

- Heat transfer1

- Electric currents2

- Piezoelectricity2

- Piezoresistivity2

- Poroelasticity3

- Acoustics–composite interaction4

- Fluid–composite interaction5

- Requires the Heat Transfer Module

- Requires the AC/DC Module or MEMS Module

- Requires the Porous Media Module

- Requires the Acoustics Module

- For turbulent flow, requires the CFD Module

Heat Transfer and Electric Currents

Model Joule heating and thermal expansion inside a composite laminate with layered material technology.

Piezoelectricity

Embed a piezoelectric material in a composite laminate to model thin piezoelectric devices and sensors.

Acoustics–Composite Interaction

Model vibroacoustics by coupling the composite laminate with a surrounding acoustic domain.

Fluid–Composite Interaction

Use the Shell interface to model composite laminates interacting with fluid domains.

Every business and every simulation need is different.

In order to fully evaluate whether or not the COMSOL Multiphysics® software will meet your requirements, you need to contact us. By talking to one of our sales representatives, you will get personalized recommendations and fully documented examples to help you get the most out of your evaluation and guide you to choose the best license option to suit your needs.

Just click on the "Contact COMSOL" button, fill in your contact details and any specific comments or questions, and submit. You will receive a response from a sales representative within one business day.

Next Step

Request a Software Demonstration