Reservoirs, dams, and other outdoor structures need to be strong, reliable, and sound. The porous materials found within these structures can be easily damaged by pressure changes that cause fluid flow and gradual caving and sinking. Using the multiphysics simulation capabilities of COMSOL Multiphysics and the Poroelasticity interface, we can accurately analyze porous materials to evaluate and avoid deformation in such structures.

Studying Poroelasticity to Build Strong Foundations

Take a hike in a nearby forest and you’ll come across various examples of porous media: ground soil, rocks, and even your own biological tissue. A porous medium is made up of a solid material, called a porous matrix, which contains a network of connected pores saturated with fluids. Consider a basic kitchen sponge that is completely saturated with water, for instance. This is an example of a porous medium.

Porous rock formations found on Mono Lake in California.

When a porous matrix is made up of a solid elastic material, and the fluid inside is viscous, this aggregate is known as poroelastic material. The study of poroelasticity has applications in geomechanics for structures such as reservoirs, dams, and energy piles. The Leaning Tower of Pisa is one well-known historical example of the negative outcome of building onto clayey porous soils.

Studying poroelasticity helps us predict the damage that can occur in a solid. For instance, in a reservoir, fluid is pumped out and the reduced pressure creates fluid movement that causes in situ stresses. Such stresses trigger gradual deformation in the overburdens above the formation, causing some of the layers to cave in or sink. Gradual deformation can continue over time, leading to the eventual cracking of the design.

As we’ll highlight here, multiphysics simulation offers valuable insight into how porous materials behave in the real world, helping us address and prevent potential deformation in geotechnical structures.

Using COMSOL Multiphysics to Analyze Porous Structures

The analysis of porous materials is a true multiphysics problem in that it requires the coupling of fluid flow and structural mechanics and commonly heat transfer as well. The physics behind poroelasticity can be investigated using the Biot theory, which is made up of two main physical laws:

- Linear elasticity equations describe the porous matrix

- Darcy’s law describes fluid flow through the matrix

The Poroelasticity coupling in the Subsurface Flow Module allows for the numerical coupling of Darcy’s law and solid mechanics. This enables you to evaluate how a porous medium is deformed due to fluid flow and changes in pore pressure. Let’s look at two instances of studying poroelasticity in COMSOL Multiphysics.

Deformation in Reservoirs

Reservoirs often need to be pumped in order to harvest the valuable fluid inside, such as oil or water. Pumping the fluid generates a decrease in pressure in the pores, which can cause the surrounding sediment to sink. This process leads to vertical compaction and lateral stretching in the reservoir.

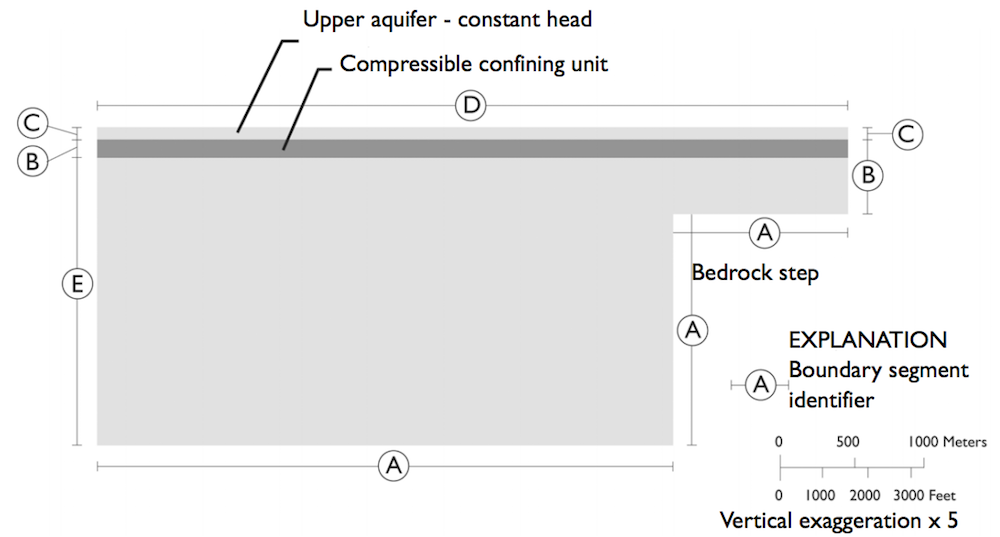

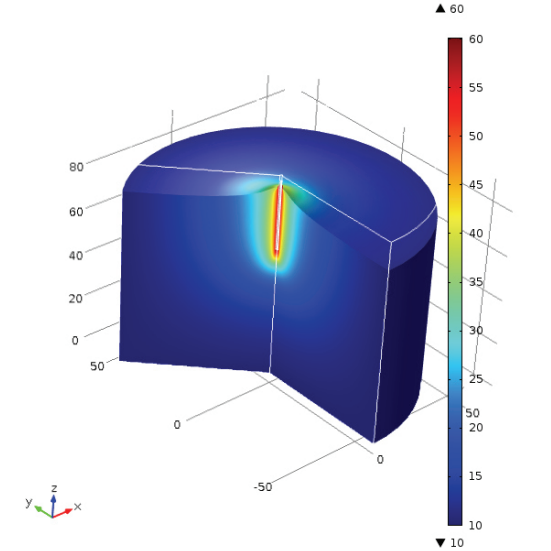

In the Biot Poroelasticity tutorial model, we can analyze the behavior of the fluids and solids in the basin of a reservoir with three sediment layers over an impermeable layer of bedrock. In our model, the top two layers have the same thickness, while the bottom layer is deepest at the centerline and the bedrock layer is faulted, creating a “step”.

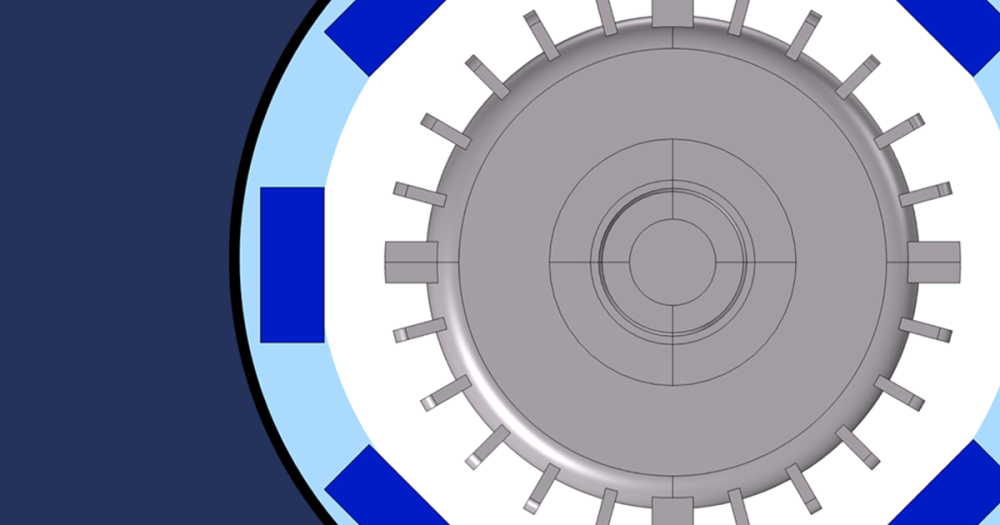

The geometry of an oil reservoir.

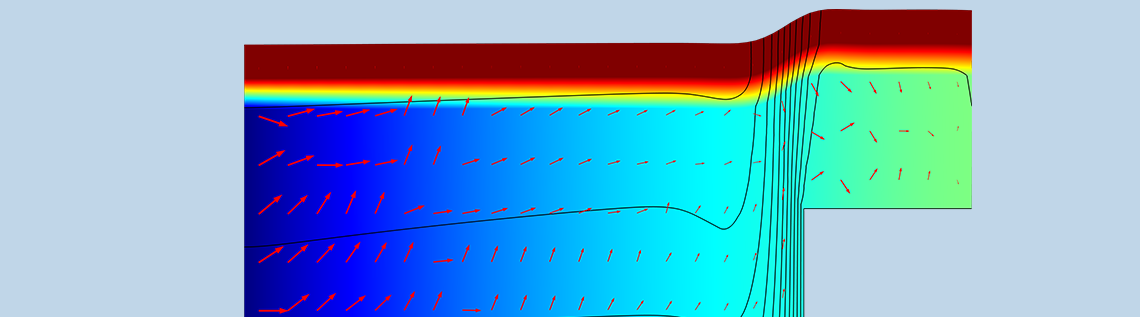

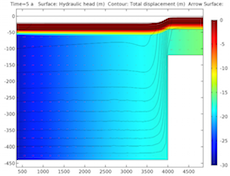

Using the Poroelasticity interface, we can set up a two-way coupled analysis of fluid flow and solid deformation in the basin. The simulation starts with fluid pumping from the centerline and flowing from left to right. The pumping process causes the fluid in the basin to pull away from the step. Through the results, we can observe changes and deformation in the layers over two, five, and ten years.

Deformation in the reservoir basin after two (left), five (middle), and ten (right) years.

The plots above show that pumping causes the basin’s layers to compensate for changes in pressure by shifting laterally, resulting in gradual deformation in the structure.

Energy Pile Performance

Heat transfer is another common physics area that needs to be considered when studying fluid flow and structural mechanics in porous materials. Energy piles, which are heat exchangers located within building foundations for effective heating and cooling, are one application that demonstrates this problem.

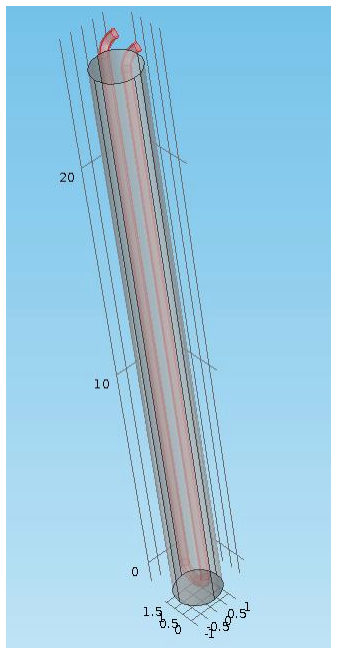

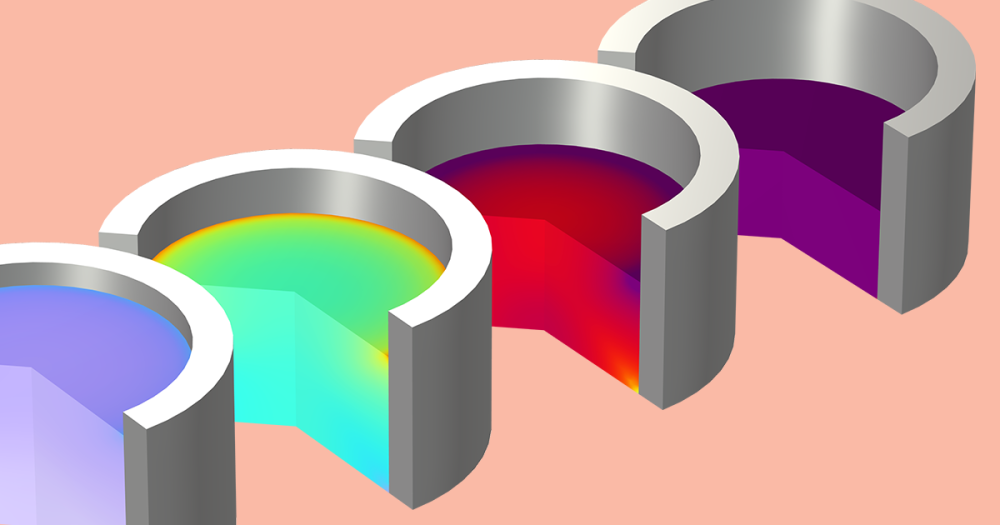

The geometry of a basic energy pile. Image by E. Holzbecher and taken from his COMSOL Conference paper submission.

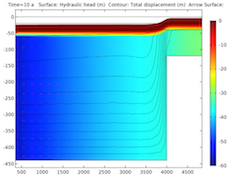

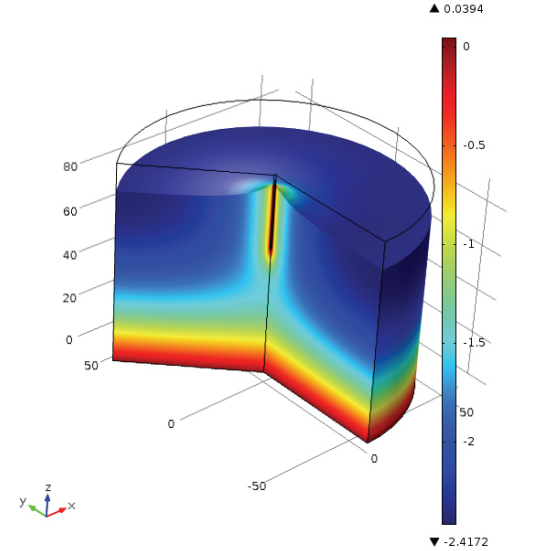

Within an energy pile setup, groundwater can flow through the porous matrix of a building foundation and change the temperature distribution around the device. The fluid flow can also produce a change in the pore pressure and affect the stability of the subsurface material. A team of researchers used numerical coupling in COMSOL Multiphysics to investigate how thermal effects can exaggerate deformation in the energy pile structure and adjacent ground.

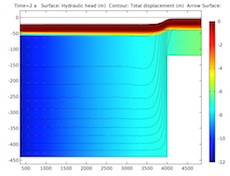

The temperature distribution (left) and vertical displacement (right) for a model of one energy pile in a porous structure. Images by E. Holzbecher and taken from his COMSOL Conference paper submission.

The results show that while thermal stress and expansion can have a great effect on the deformation of the energy piles and building structure, fluid compressibility and the thermal properties of the groundwater have negligible and very minor effects, respectively.

The ability to easily couple numerical studies in COMSOL Multiphysics enables us to thoroughly analyze porous structures and evaluate how a porous material will perform in the real world. This, in turn, fosters the development of safer structures and improved geotechnical designs.

Learn More About Using Simulation to Analyze Poroelasticity

- Try it yourself: Download the Biot Poroelasticity tutorial model

- Read the full paper from the COMSOL Conference 2014 Cambridge: “Energy Pile Simulation — an Application of THM-Modeling“

- Browse the COMSOL Blog for additional discussions on poroelasticity:

Comments (0)